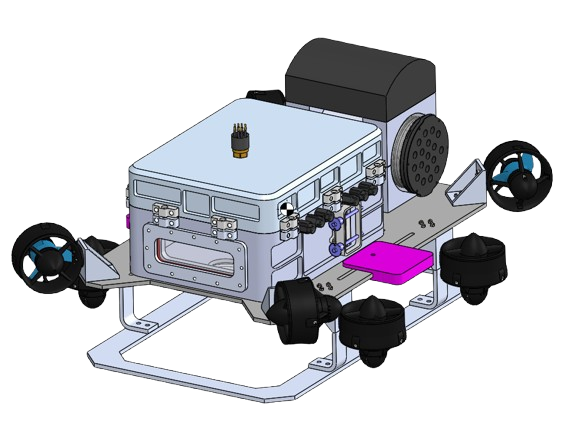

MEET P.I.G.E.O.N

Nautilus’s AUV is named P.I.G.E.O.N. The name comes from “Platforme Immersive pour Gambader En Océan Non-stop.” After more than 100 hours of work, the Nautilus team is very proud to present the result of these efforts. You can visit the different sections (electrical, mechanical, and software) to learn more about its design.

Waterproof electrical enclosure rated up to 10 m

8 thrusters enabling navigation in all 6 degrees of freedom

Dual-layer layout to allow modularity of the modules

The technical report of the submarine designed as part of the competition is available below.

MECHANICAL

The mechanical aspect can be divided into two sections: the structure and the electronics enclosure.

The submarine structure is made of aluminum, which was subsequently anodized to improve corrosion resistance. This structure consists of two levels: an upper level that allows for the integration of the electronics enclosure, the thrusters, and the battery compartment, and a lower level that allows for the installation of additional modules such as the torpedo launcher and the gripper.

Regarding the electronics enclosure, it was custom-designed to meet the specific needs of our team. It is machined from a solid block of aluminum and will also be anodized. The enclosure includes two windows to enable underwater navigation using cameras. It was designed to withstand depths of up to 10 m.

ELECTRICAL

The submarine is powered by a 14.8 V battery, providing an autonomy of approximately 2 hours. This battery supplies power to the various components essential for proper operation of the submarine, such as the thrusters, onboard computer, DVL, cameras, and temperature, humidity, and pressure sensors. Depending on their input voltage requirements, the different components are powered through separate voltage rails.

The submarine is also equipped with an emergency stop system that allows all power to be completely cut off from the various components. This system operates using magnetic principles to ensure reliable activation.

All components are mounted on an electrical board that was 3D printed to optimize the internal space of the electronics enclosure.

SOFTWARE

The Nautilus team uses the ArduSub platform as the foundation for the submarine’s software architecture to control and manage vehicle motion. All control is handled by a Pixhawk flight controller, which processes navigation commands and implements the closed-loop control system of the autonomous underwater vehicle (AUV).

Due to the limited opportunities for in-water testing, the software team also relies on a simulation environment for development and validation. This environment accurately models underwater physics, which is particularly important given the significant differences between aerial and underwater dynamics. The simulation framework enables safe and efficient testing of the various competition tasks, allowing algorithms and mission logic to be validated prior to real-world deployment.